Công ty cổ phần công nghệ và tư vấn CIC

Steel industry solutions Consultancy

Overview of consulting services for applied technology solutions for the steel industry

With more than 30 years of experience operating in the field of applied technology in construction, transportation, planning, infrastructure, energy, oil and gas, mining... CIC is currently a partner of famous software companies. world famous in the field of construction & mechanical manufacturing such as CSI (USA), Bentley (USA), IdeaStatica (Czech), Alma (France), Adapt (USA), Trimble (USA), Geo-Slope (Canada ), Rapt (Australia), Glodon (Singapore)... with many groups of software solutions applied in different specific industries. Including a series of application solutions for the steel structure and heavy industrial mechanical industries.

Application solutions for the steel industry are based on a closed working model between design engineers, model engineers, detailed implementation engineers and manufacturing engineers based on the software that CIC is distributing. delivery: SAP2000/ETABS – analysis and design of frame structures, floor beams or shell panels <-> IdeaStatica Steel – design and check of steel connections <-> Tekla (BIM Tool) – model and structure of steel structures & construction <-> AlmaCAM – deploying arrangement and optimization of steel cutting, material management.

1. Structural design phase

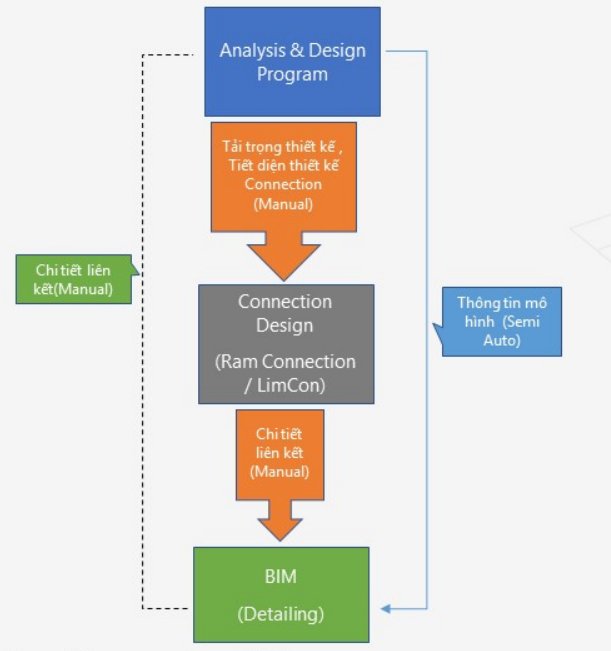

The usual way to do it is according to the diagram below

With the traditional method, design engineers will use analysis and design programs such as SAP2000, ETABS, STAAD.PRO, Robot... to calculate the bar cross section and get internal force results. These results will be transferred to the steel connection calculation department using tools such as Ram Connection, Limcom or Excel spreadsheet to calculate the connection. The associated details are then passed on to the model implementation department using a BIM tool such as Tekla, Revit or Advance Steel.

Working under the old model will have the following limitations:

The process of converting information between the frame design department and the connection design department is completely manual, which can lead to errors.

The conversion between the frame design department, the link design department and the BIM department is also completely manual.

During the design process, if there are changes or changes to the plan, the process will be repeated the beginning, leading to a lot of time wasted.

The BIM modeling department has to wait for the design department to complete before it can be deployed, leading to a loss of time for the whole system.

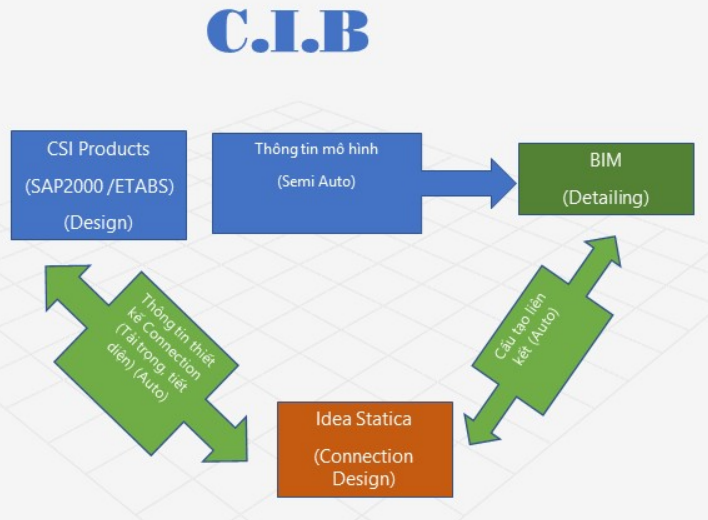

How to follow the C.I.B combination model:

With CIC's C.I.B solution chain application model, by applying SAP2000, ETABS, IdeaStatica, Tekla (BIM) software, creating a closed process chain frame structure design, BIM model, and link check calculation. After the frame structure design department's work is finished, the entire bar section will be transferred to the Tekla (BIM) department to make the steel connection structure. After structuring the nodes that link the parts, Tekla (BIM) will transfer the node structure model to the connecting parts and at the same time take internal resources SAP2000, ETABS to IdeaStatica Steel software to check and redesign the links. bond if it is not strong enough to bear the force.

The conversion of models and internal force information between parts is completely automatic, without errors.

Conducting the project almost in parallel between departments will help save time for the entire project.

Changing plans or changes the investor is no longer a worry because the process is completely automated, changes will be automatically synchronized to avoid errors and no need to redesign scratch like traditional method.

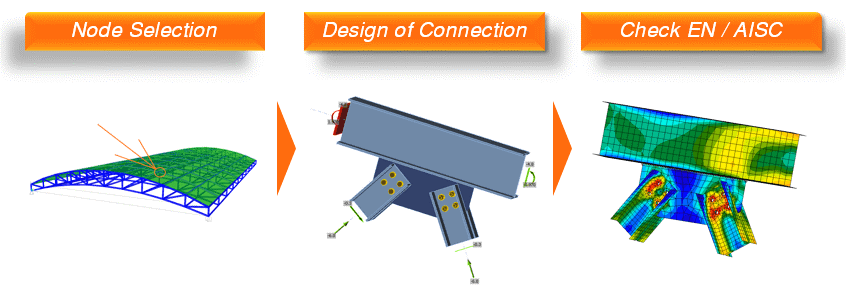

Internal force transfer model SAP2000 ->IdeaStatica Steel

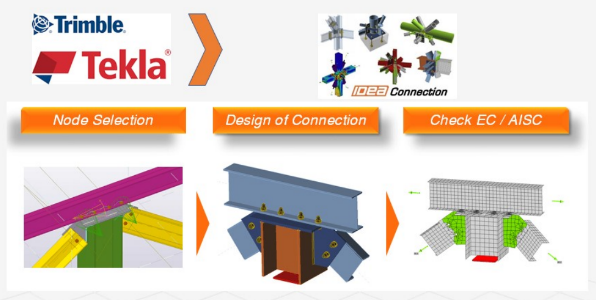

Model for transferring node structure Tekla -> IdeaStatica

2. Manufacturing stage

After having a BIM model with frame structure details, steel connections and other related mechanical parts such as scrapers, troughs, floor panels... will be exported completely automatically to the manufacturing department. With steel cutting, instead of exporting drawings to engineers to arrange cutting through AutoCAD software or regular nesting software. With our technology, this step will be applied with steel cutting & smart materials management software that AlmaCAM brings.

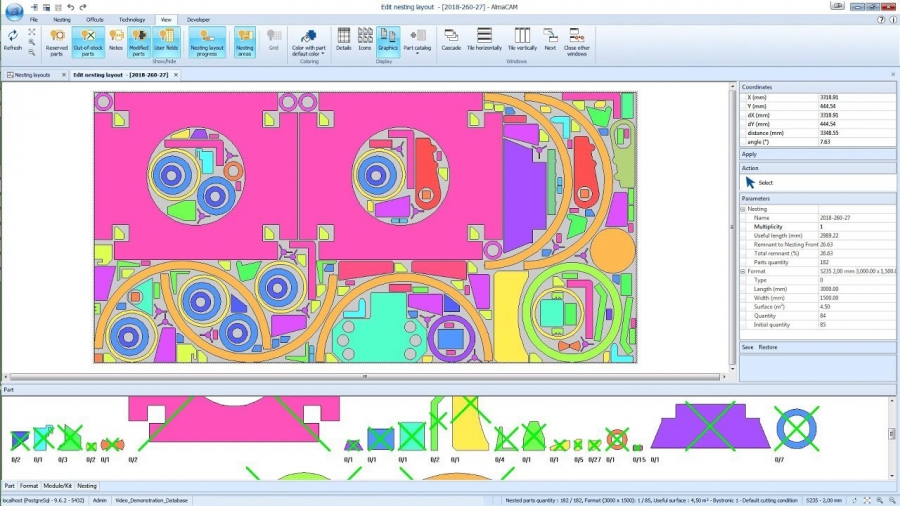

Optimal steel cutting layout on AlmaCAM software parts exported Tekla

Benefits of applying automatic steel cutting process parts transferred Tekla->AlmaCAM:

Data conversion is fully automatic

Marking and classifying parts is completely automatic

Classification of material thickness and material properties is completely automatic

Manage excess supplies and components in inventory for reuse in future projects

Sorting and searching for materials in the warehouse that match the parts of a project is completely automatic.

With the above solution, what products and services does CIC provide to your company:

Copyrighted software is distributed through official channels of companies.

Consulting on choosing the right version for your work needs to help save investment costs.

Training on transfer the design stage to the manufacturing and application stage for the production process.

Steel structure optimization service helps reduce volume, material costs...

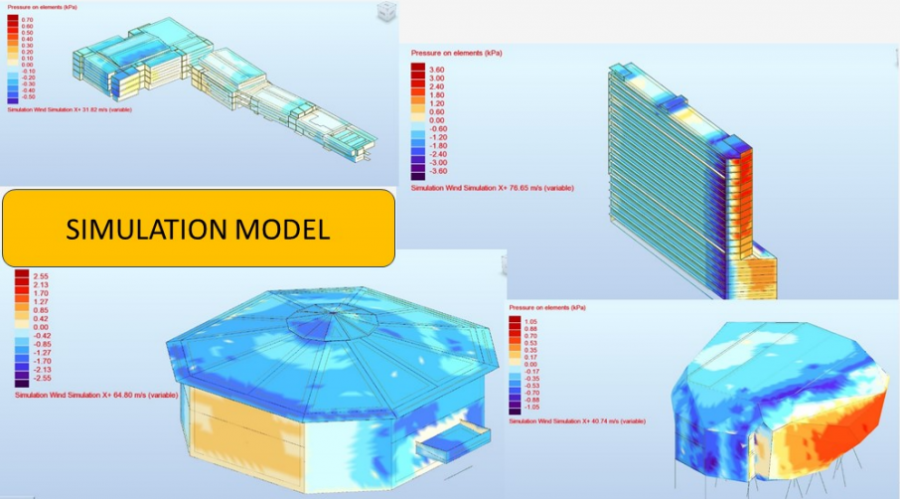

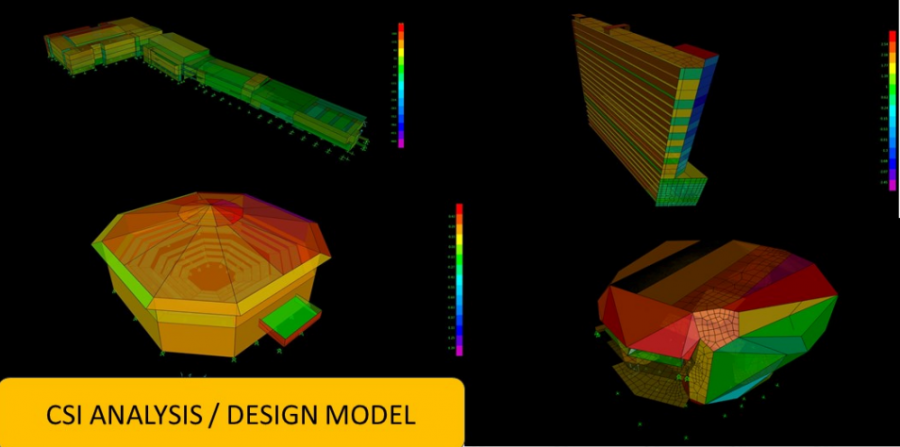

Service of simulating wind blowing and assigning forces after wind stops to structural design analysis software as required.

Consulting services handle issues related to structures and projects with complex connections.

Wind turbine model on software

The CSI SAP2000/ETABS software model receives force the wind blowing process